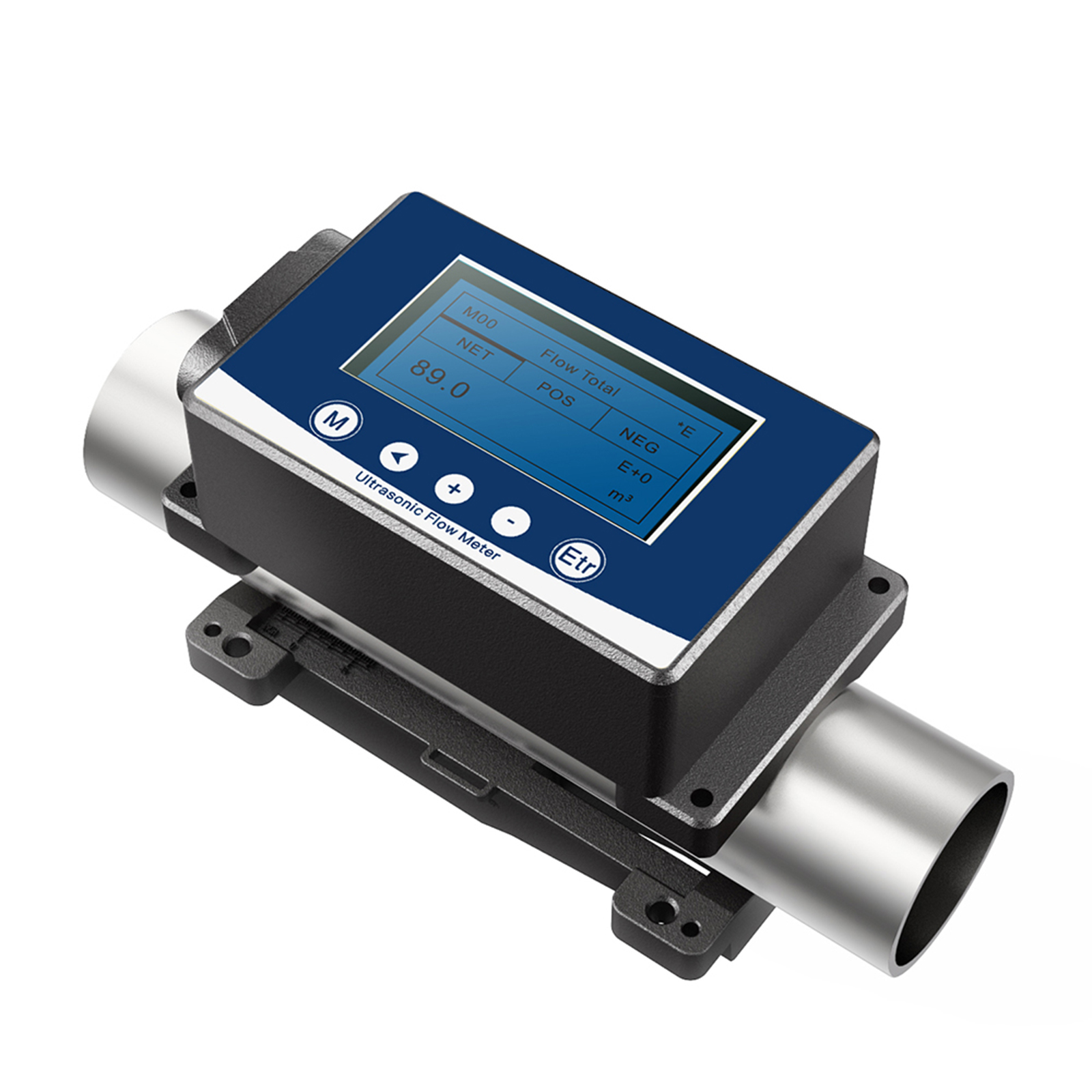

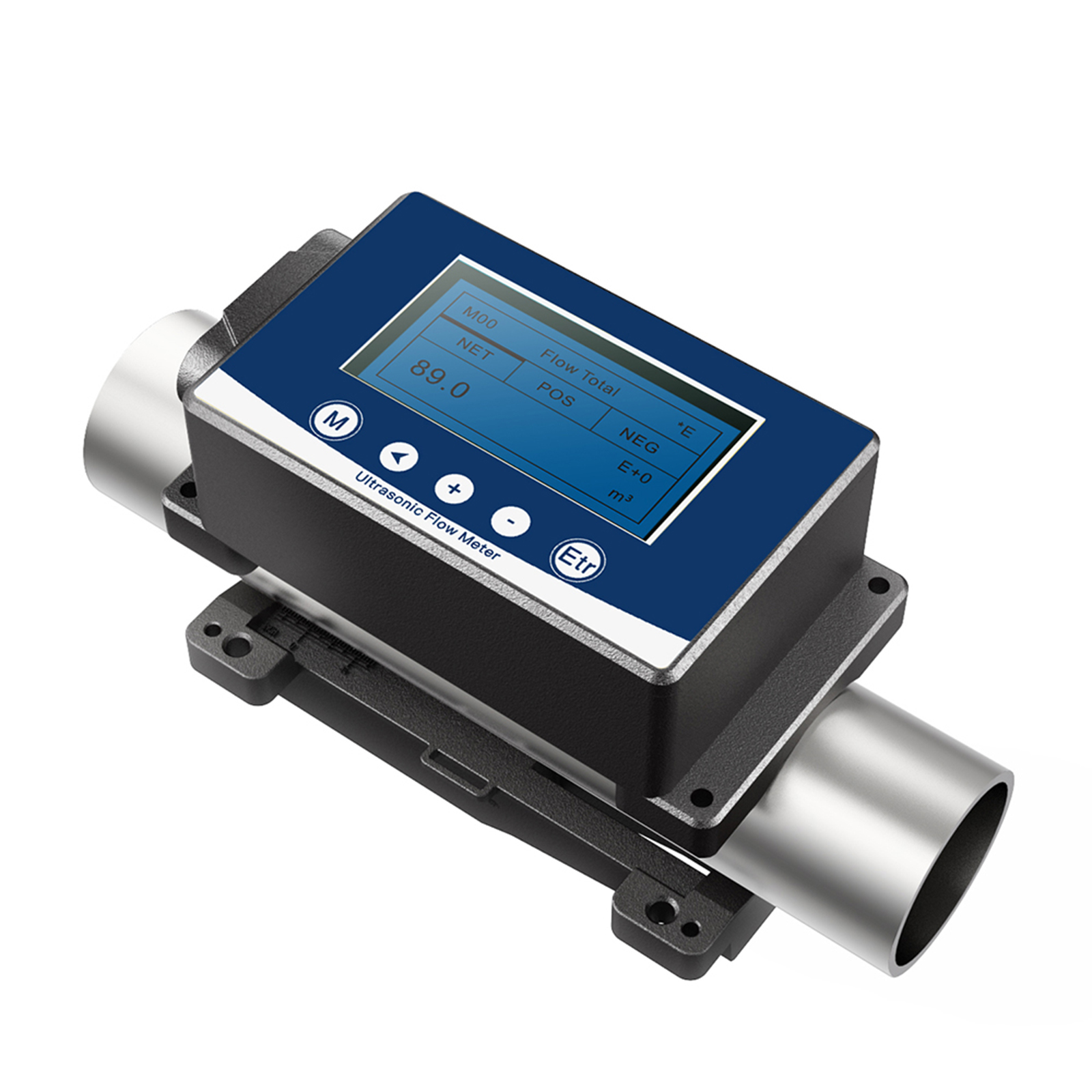

clamp on ultrasonic flow meter for water

Email: sales01@cxflowmeter.com

whatsapp:008618049841995

Clamp-on

ultrasonic water flow meter, also known as external clamp-on ultrasonic flow meter, is an instrument used to measure water flow in pipelines.

working principle

The clip-on

ultrasonic water flow meter works based on the principle of ultrasonic propagation time difference. Its main feature is to install sensors outside the pipeline, use the

characteristics of the propagation speed of ultrasonic waves in the fluid to change due to different fluid flow rates, and calculate the flow rate of the fluid by measuring the

transmission time difference of the ultrasonic waves, and then obtain the flow rate.

Technical Parameters

Measurement principle: Ultrasonic propagation time difference principle, dual CPUs working in parallel, 4-byte floating point operation, measurement period 500ms, 2 times per second.

Signal input and output: 5 channels of current signals (such as temperature, pressure, liquid level, etc.) can be input, with an accuracy of 0.1%; the output includes 4-20mA or 0-20mA

current signals, frequency signals (12~9999Hz), pulse signals (positive, negative, net flow and heat cumulative pulses), alarm signals, etc.

Communication interface: full-featured RS232 serial interface, optional RS485 or CAN bus.

Pipe material: Supports steel, stainless steel, cast iron, cement pipes, PVC, aluminum, copper and other dense pipes, and lining is allowed.

Measuring medium: Suitable for water, seawater, drinking water, river water, groundwater cooling water, high temperature water, sewage, lubricating oil, diesel, fuel chemical liquid and

other uniform liquids that can conduct sound waves.

Medium temperature: Measuring range is -30~150℃.

Diameter range: DN15~DN6000.

Flow velocity range: 0~±32m/s.

Measurement accuracy: better than ±1%, one of the few ultrasonic flowmeters in China that can achieve this accuracy.

Power supply: supports AC220V or DC8-36V or AC7-30V.

Advantages and Disadvantages

advantage:

Non-contact measurement: no need to destroy the pipeline, easy and quick installation.

No pressure loss: no movement to hinder measurement, no pressure loss.

Can measure non-conductive liquid: it is a supplement to the electromagnetic flowmeter for non-obstruction measurement.

High cost performance: simple installation and high cost performance.

shortcoming:

The temperature measurement range is limited: generally it can only measure fluids with temperatures below 200°C.

Poor anti-interference ability: It is susceptible to interference from bubbles, scaling, ultrasonic noise mixed in from pumps and other sound sources, affecting measurement accuracy.

The straight pipe section has strict requirements: it needs to be 10D in front, 5D in back, and 30D away from the pump (D is the inner diameter of the pipe), otherwise the discreteness

will be poor and the measurement accuracy will be poor.

Installation uncertainty: It will bring large errors to flow measurement.

Effect of scaling: scaling on the measuring pipe will seriously affect the measurement accuracy, and even cause the meter to have no flow display.

Typical uses

Clamp-on ultrasonic

water flowmeter is widely used in water, sewage, seawater measurement, as well as hull operation and maintenance, water supply and drainage, energy saving

monitoring, water saving management, power plants, paper and pulping, heat, heating, heating, leak detection , flow, thermal management and monitoring network systems in metallurgy,

mining, petroleum, chemical, food and pharmaceutical industries.

If you have a purchase plan for

clamp type flow meter, please feel free to consult CIXIFM winny:

Email: sales01@cxflowmeter.com

whatsapp:008618049841995