How to choose electromagnetic flow meter?

sales01@cxflowmeter.com

Magnetic flow meter is an instrument that uses the principle of electromagnetic induction to measure the flow of conductive fluid according to the electromotive force induced by the conductive fluid passing through an external magnetic field. Therefore, the measured liquid fluid must have conductivity.

The structure of electromagnetic flowmeter is mainly composed of magnetic circuit system, measuring conduit, electrode, shell, lining and converter.

Selection of caliber and range

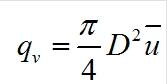

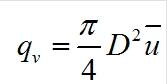

The diameter of the transmitter is usually the same as that of the piping system. If the channel dividing system is to be designed, the caliber can be selected according to the range of the flow mother and the flow rate. For electromagnetic flowmeters, the flow velocity is more suitable at 2-4m/s. In special cases. If there are solid particles in the liquid, considering the wear condition, the commonly used flow velocity can be ≤3m/s. For the fluid that is easy to attach to the pipe wall, the flow velocity can be selected ≤2m/s. After the flow velocity is determined, it can be selected according to

to determine the diameter of the transmitter.

The range of the transmitter can be selected according to two principles: one is that the full scale of the instrument is greater than the expected maximum flow value, and the other is that the normal flow value is greater than 50% of the full scale of the instrument to ensure a certain measurement accuracy.

lining options

The lining material should be selected according to the corrosiveness, abrasiveness and temperature of the measured medium:

1. Natural rubber (soft rubber)

1. Good elasticity, wear resistance and tearing force

2. Resistant to general weak acid and weak alkali corrosion

3. Measuring water and sewage

2. Acid-resistant rubber (hard rubber)

Resistant to the corrosion of hydrochloric acid, acetic acid, oxalic acid, ammonia water, phosphoric acid and 50% sulfuric acid, sodium hydroxide, potassium hydroxide at room temperature, but not resistant to strong oxidants

Measure general acid, alkali and salt solution

3. Neoprene

1. Excellent elasticity, high breaking force, good wear resistance

2. It is resistant to corrosion by general low-concentration acid-base and salt solutions, but not resistant to corrosion by oxidative media

<80℃;

Water, sewage, mud and slurries

4. Polyurethane rubber

1. Excellent wear resistance

2. Poor acid and alkali resistance

<40℃

Measure neutral and highly abrasive coal slurries, slurries and ore slurries

5. Polytetrafluoroethylene (PTFE)

1. Resistant to boiling hydrochloric acid, sulfuric acid, nitric acid, aqua regia, concentrated alkali and various organic solvents

2. Good wear resistance and poor adhesion

-80~+180℃;

Concentration measurement, concentrated alkali strong corrosive solution and hygienic medium

Application site selection

1. Understand the process parameters

(1) Know the name of the liquid to be tested (provided by the user)

(2) Understand the maximum flow, common flow, and minimum flow of the liquid to be measured (provided by the user)

(3) Understand the process pipe diameter (provided by the user)

(4) Understand the medium temperature (provided by the user)

(5) Understand the medium pressure (provided by the user)

(6) Understand the conductivity of the fluid to be measured (provided by the user)

(7) Find out if there is negative pressure (provided by the user)

sales01@cxflowmeter.com